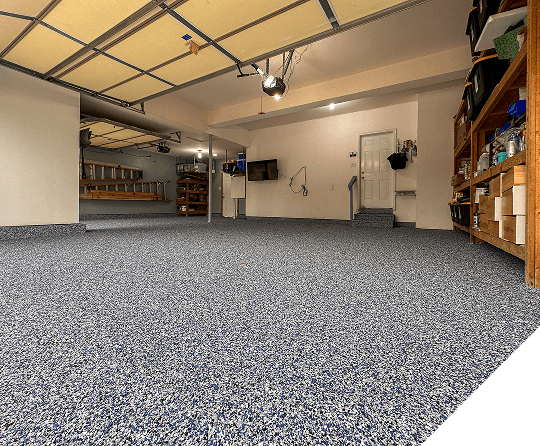

Need a tough floor coating solution for your garage? Level 10 Coatings installs a premium concrete coating with a signature flake system that enhances the appearance of your garage and improves its durability. Our solutions breathe new life into spaces in need of a sturdy and easy-to-maintain floor.

Your garage’s concrete floor takes a lot of wear and tear from vehicles, heavy equipment, foot traffic, and even weather. A damaged and stained floor makes your garage look uglier and can be harmful to your vehicle’s tires. Additionally, pits and cracks can pose safety risks.

At Level 10 Coatings, we’re committed to delivering the “Level 10 Experience” to each of our customers. From the moment you book your consultation to the final installation of your new floor, you will receive nothing short of outstanding customer service.

Our team is here to guide you through the entire process and answer any question you have about the installation. Level 10 is here for you!

We tailor every project to meet the needs of your home or business. This ensures the final result aligns with your vision and functional requirements.

We are at the forefront of the coatings industry and consistently adopt the latest technologies and best practices to deliver superior results.

Level 10 Coatings has thousands of satisfied customers and over 500+ Verified Reviews on Google. We’ve earned a strong reputation for quality and reliability in the community.

Unlike many of our competitors, we use a highly trained in-house team for all installations. This ensures consistent quality, accountability, and NO subcontractors!

We have a well-established, proven process that guides you from start to finish, ensuring you have support and clear communication.

We have in-depth experience completing diverse commercial and residential projects. We have the capability and expertise to handle your project with care.

Level 10 Coatings provides homeowners with durable, impact and slip-resistant floor coating options. Our garage floor coatings are installed with industrial grade products and are designed to withstand the test of time.

Review and approve the estimate. We provide information so that clients can make an educated decision. Before deciding to move forward with your project, you will approve the project price.

Once approved, you’ll choose your preferred installation time. Our Level 10 Team will provide you with our signature Level 10 Experience!

Sit back and admire your brand-new premium concrete coating! We offer post-install aftercare. If you discover any issues with your floor, we offer a lifetime warranty and a guarantee of quality workmanship.