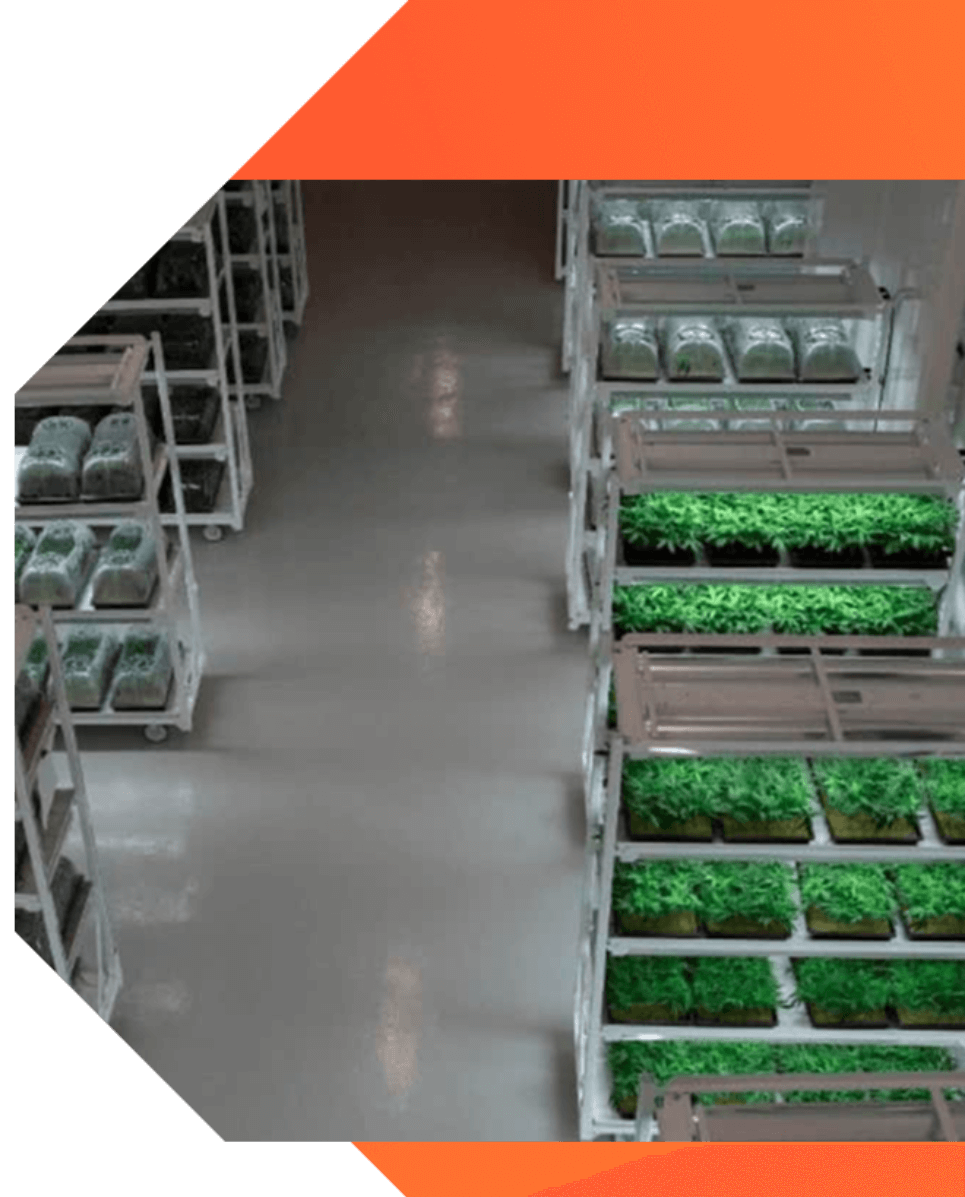

Grind and seal flooring offers a budget-friendly way to protect and enhance commercial concrete floors. By mechanically grinding the concrete and applying a durable coating, this method provides reliable protection at a lower cost.

If you prefer a more natural look, Level 10 can apply a sealer instead. This option is also cost-effective and maintains the concrete’s original appearance and texture, though it does reveal natural imperfections.

We have extensive experience with commercial flooring and understand that every client has unique requirements. Our team can provide customized grind-and-seal options to fit your specific needs and budget.

Whether you’re looking for a protective coating or a cost-effective sealer that maintains the concrete’s natural appearance, Level 10 has you covered.

Grind and Seal flooring is more affordable than polished concrete. It offers a cost-effective way to protect and enhance concrete floors without the higher upfront investment.

This makes it an ideal choice for projects with budget considerations.

A Grind and Seal floor can be customized to achieve a matte, satin, or glossy appearance.

The final look depends on the type of sealer used, giving you flexibility to match your space’s style and design.

At Level 10 Coatings, we tailor our Grind & Seal process to the customer’s needs and budget. We use either polyaspartic or acrylic sealers, depending on the desired durability, chemical resistance, and aesthetics.

Using a polyaspartic sealer is the premium option while an acrylic sealer is a more budget-friendly choice.

A Grind and Seal floor is ideal for industrial, commercial, and residential applications where a sealed surface is preferred for moisture or stain resistance.

If you have a floor that only receives light to moderate foot traffic, then Grind and Seal is a good option.

Compared to polished concrete, Grind and Seal is faster and less labor-intensive.

The process requires the concrete surface to be ground to the desired level of smoothness, then sealed with a topical coating (epoxy, polyurethane, or acrylic sealer).

We understand that a long downtime isn’t an option for most businesses. For this reason, our Grind and Seal services are designed for efficiency and speed while never compromising on quality.

We offer flexible scheduling and clear timelines, so you always know what to expect. Our goal is to deliver a seamless experience from start to finish.